Manufacturing Optical Viewing Equipment Since 1969

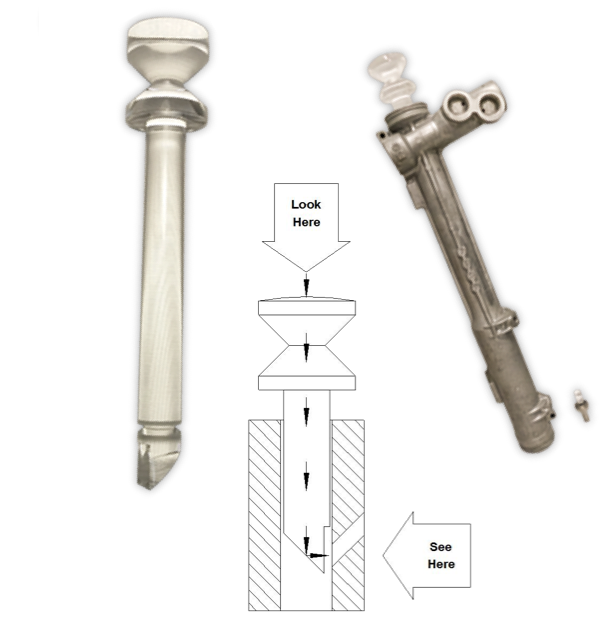

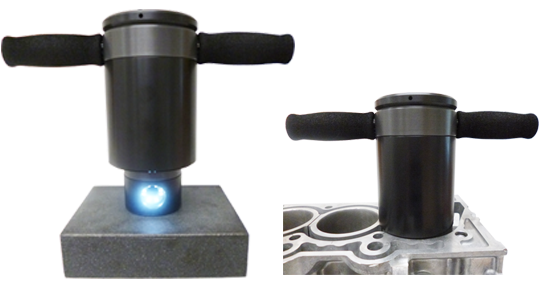

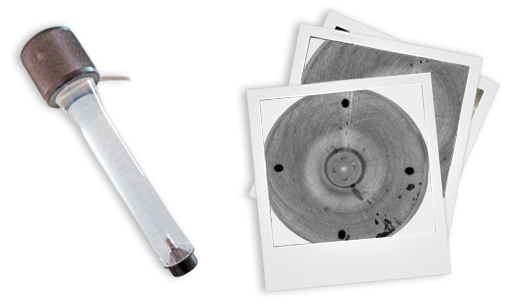

SIGHT-PIPE® Optical Viewers

A practical, economical solution to viewing “difficult to inspect” internal characteristics.

Special Sizes

In addition to the standard size SIGHT-PIPE® products available, specific diameters and lengths can be manufactured.

Custom Viewing and/or Gaging

A variety of custom SIGHT-PIPE® products have been designed and manufactured to view and/or gage internal characteristics.

Since 1969, we are proud to have provided inspection solutions worldwide to manufacturers such as Ford, GM, Honda, Caterpillar, TRW and Swagelok as well as many automotive component manufacturers and manufacturers using orbital tube welding. We look forward to working with our customers in the future.