GAP DETECTION GAGE WITH SCALE:

This Gage is used in cylinder heads to visually confirm intake and exhaust inserts have been pressed in correctly with no gaps present.

Gage is placed in certified master to calibrate the software to the master.

When Gage is placed into head if a gap is present the scale on the monitor is used to approximate gap size.

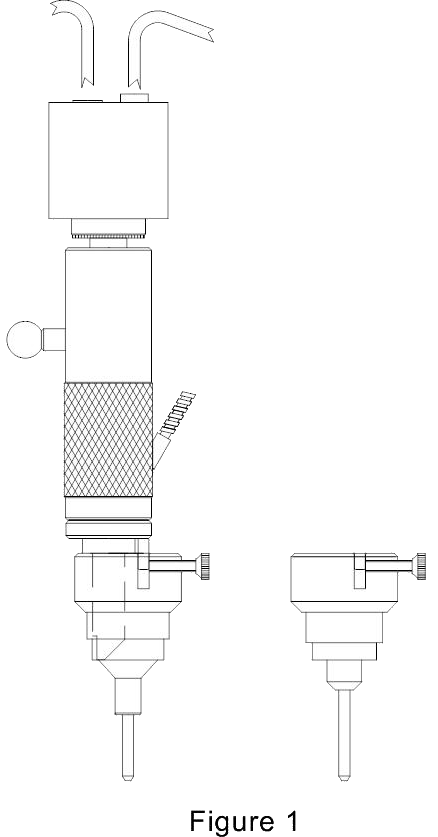

Gage is custom designed for each application and includes one SIGHT-PIPE(R) BOREVIEW(TM), Positioners; one for Intake and one for Exhaust, VIDEO TOOLBOX PRO (TM) software, camera, optics, adjustable lighting and certified master (Figure 1). Customer provides computer.

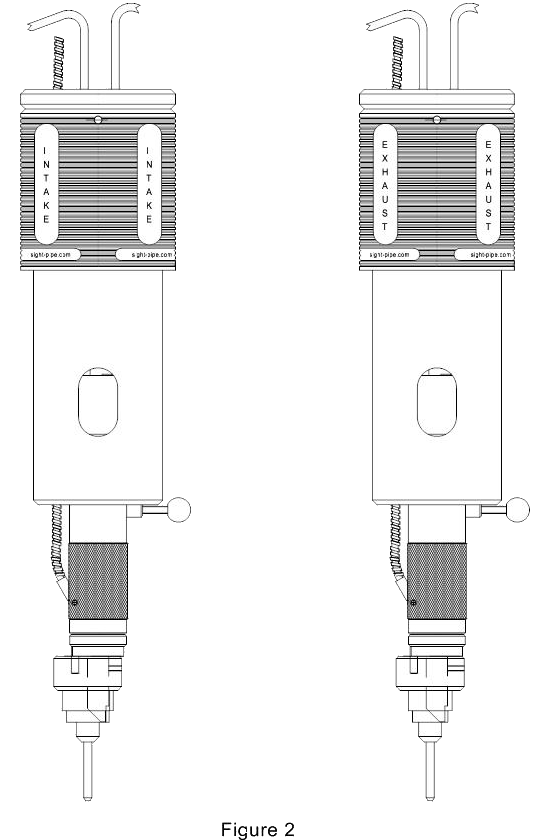

This Gage can also be designed to be dedicated, where there is one complete Gage for Intake and one complete Gage for Exhaust, thus eliminating the need to switch Positioners. Our software allows switching between two cameras with an electronic A-B switch (Figure 2).